Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Material Science

Researchers at Kyushu University in Japan are developing new methods for capturing the carbon dioxide (CO2) emissions that are produced by coal-fired power plants, steel manufacturers, and other industrial plants. CO2 is the gas considered most responsible for global climate change. Using Imaris software, the researchers were able to gain information that can be used to design and develop new materials for CO2 separation.

Dr. Ikuo Taniguchi, an associate professor at the University’s International Institute for Carbon-Neutral Energy Research CO2 Capture and Utilization Research Division, is leading the research team. The investigators are studying a membrane made of a blend of poly(amidoamine) (PAMAM) dendrimer immobilized in a PEG dimethacrylate network. Dendrimers such as PAMAN have a central core in which small molecules can be entrapped and branching functional groups that allow it to be modified for specific applications. When used in a liquid immobilized membrane, the PAMAM dendrimer exhibits preferential permeation CO2 over N2 or O2, making it a good candidate for of is key for CO2 capture technologies.

The researchers wanted to better understand the effect of PEG length and humidity on the membrane’s CO2 separation properties so that they could learn more about the mechanism behind the membrane’s preferential CO2 permeation. “The distribution and the phase-separated structure of the dendrimer are important factors that determine the CO2 separation properties of the polymeric membrane,” Dr. Taniguchi said.

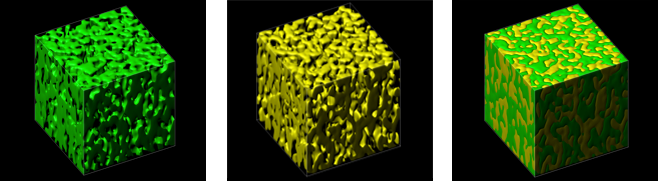

To analyze the structure of the membrane, the researchers turned to confocal microscopy because of its ability to capture the three-dimensional morphology of a polymeric blend. They fabricated a membrane that incorporated fluorescein-labeled PEG to visualize the PEG-rich phase. Two-dimensional confocal images of the membrane were processed and then the researchers used Imaris to create 3D reconstructions that showed the interface of PEG and the PAMAM dendrimers.

The polymeric membrane is composed of PAMAM dendrimer (yellow) and PEG matrix (green), in which each fraction is 50 wt% (22 × 22 × 22 microns ). Images courtesy of Ikuo Taniguchi.

The investigators also used Imaris to quantify numerical the volume fractions, interface area, and other characteristics of the phase-separated structure. “Using the software we gained information about the interplay between the detail phase-separated structure and the CO2 separation properties of the polymeric membrane,” Dr. Taniguchi said.

The analysis revealed polymerization-induced phase separation on a micron scale and the formation of a bicontinuous structure of PEG-rich and PAMAM dendrimer-rich phases. They were also able to determine that a higher CO2 permeance resulted from a higher CO2 sorption by the PAMAM dendrimer because of

Research paper: Ikuo Taniguchi, Shuhong Duan, Teruhiko Kai, Shingo Kazamab and Hiroshi Jinnaiacd. 2013. Effect of the phase-separated structure on CO2 separation performance of the poly(amidoamine) dendrimer immobilized in a poly(ethylene glycol) network. J. Mater. Chem. A, 2013,1, 14514-14523.

Author: Dr. Ikuo Taniguchi and colleagues, Kyushu University

Category: Case Study