Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Material Science

Comprehensive, multi-technique characterization of multi-phase materials is a key process in understanding the three-dimensional structure of various specimens. By combining focused ion beam (FIB) / scanning electron microscopy (SEM) with X-ray spectrometry and Imaris three dimensional visualization software, it was possible to analyze metallic structures in search of corrosion sites and other structural discontinuities.

Most measurements of phase distribution and structural defects like corrosion are still based on 2D analysis of surface sections and while occasionally augmented by various imaging methods including optical or electron microscopy, they do not offer comprehensive insights into the sample’s microstructures. This goal can be achieved when such techniques are combined in one comprehensive study by providing a tool for a complex, multi-dimensional analysis without prior knowledge of the sample’s composition or spectral properties.

Such approach allowed Paul Kotula and colleagues to tackle the question of corrosion often hidden under the surface of metallic multi-phase components. In their study, a copper coupon plated with thin layers of nickel and gold was first imaged with SEM to identify the area of interest. This was then sliced in the z-dimension by focused ion beam (FIB). Each 3D slice was subsequently subjected to X-ray spectral analysis and the data was collected for successive 3D reconstruction in Imaris software.

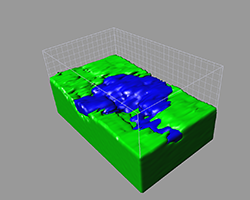

X-ray spectroscopy data has been used in multivariate statistical analysis (MSA) to extract the weakest signals from the data sets. This spectral analysis revealed some unexpected silicon oxide contaminant components in the copper coupon in addition to a corrosion product. Interestingly, when the researchers used Imaris to recreate the 3D image of their sample it became possible to visualize various 3D components of the copper coupon including the contaminant (shown in blue) that was shown to be in direct contact with the copper substrate (green).

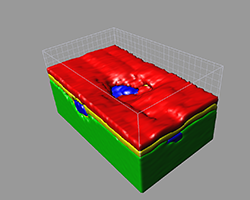

Surface rendering in Imaris made it possible to look at the finer details of the Si-O contaminant juxtapositioned between copper and the nickel (yellow) / gold (red) layers deposited by prior electroplating.

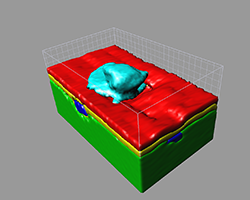

Based on the data from 3D visualizations, the researchers could note that neither nickel nor gold provided a continuous protective layer leaving a small pinhole-like opening on the surface that could lead to further localized corrosion of the substrate (shown in cyan).

This study demonstrates how a combination of several comprehensive analytical techniques provides a detailed, multi-faceted insight into samples that often are not easy to analyze with individual tools like SEM or X-ray spectroscopy.

By combining an advanced statistical analysis of the X-ray spectroscopy data with FIB slicing of the specimen and finally 3D image reconstruction and 3D surface object creation, it became possible to dissect, analyze and visualize the smallest defects in materials.

Such analyses will be of interest where the integrity of components is crucial and where the absence of processes like corrosion of phase separation is critical for maintaining the structural continuity of such components.

Research Paper: Tomographic Spectral Imaging with Multivariate Statistical Analysis: Comprehensive 3D Microanalysis. Microscopy and Microanalysis, Volume 12, 36-48 DOI: 10.1017/S1431927606060193. Sandia National Laboratories is a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000.